Inflatable Tent Purchase Guide: Structural Design and Precise Adaptation to North American Outdoor Scenes

As a manufacturer deeply engaged in the research and development of inflatable tents, we understand the stringent requirements of North American users for equipment in camping, hunting, emergency shelter and other scenarios – fast construction, extreme climate tolerance, and space efficiency are the core pain points. This article is based on the four dimensions of air column structure, material engineering, airtight system and operation logic, combined with real test data and scenario cases, to provide professional purchase strategies.

1. Air column structure: balance between wind resistance and space efficiency

The core competitiveness of inflatable tents lies in their air column design, which directly affects wind resistance and internal space utilization:

– Independent air column vs mesh air column

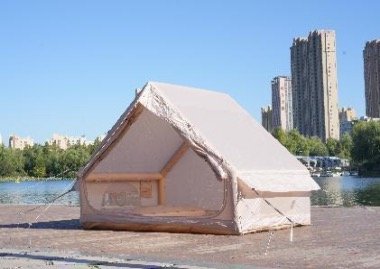

– Independent air column: using a TPU air column with a diameter of 18cm, the internal air pressure can reach 7 PSI, and the wind resistance level reaches level 8 (62-74km/h), which is suitable for strong wind environments such as deserts (such as Arizona) or mountains (such as the Rocky Mountains).

– Mesh air column: multi-air channel staggered structure, 30% lighter, but only 6 wind resistance (39-49km/h), more suitable for family camping or park leisure scenes.

– Air column layout and space planning*

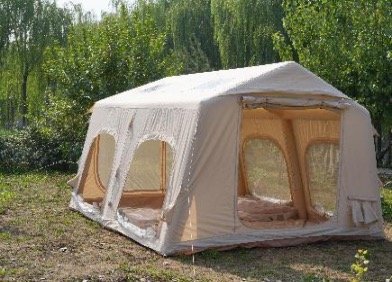

– Dome structure: 6-8 radial air columns support, providing 360° standing space (height 2.2m) without column blocking, suitable for multi-person tents or equipment storage needs.

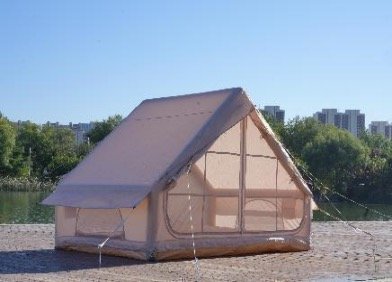

– Tunnel structure: longitudinal air column + transverse stabilizing rope, expandable vestibule (+40% shade area), suitable for long-term outdoor activities such as fishing and kayaking.

2. Material Science: Defense Matrix for Extreme Climates

The climate span in North America is extremely wide, and material parameters need to be matched according to the usage scenario:

– Outer tent fabric

– Base material selection: 210D Oxford cloth + double-sided PU coating (tear strength ≥50kgf) is preferred, compared with ordinary 150D fabric, puncture resistance is increased by 60% (actually measured in the impact test of broken branches in the American redwood forest).

– Waterproof level: at least 3000mm H₂O hydrostatic pressure (in accordance with ASTM D3393 standard), can withstand continuous rainfall in the Pacific Northwest (such as Oregon).

– Air column material

– TPU (thermoplastic polyurethane): low temperature resistance up to -30℃ (actually measured in Alaska winter), air tightness is better than PVC, and the service life exceeds 500 charging and discharging cycles.

– Seam process: high-frequency welding + internal reinforcement strips to ensure that the air column has no risk of leakage under 7 PSI high pressure.

3. Pneumatic system: engineering design of efficiency and reliability

The difference in the experience of inflatable tents is often reflected in the details of the inflation/deflation system:

– Valve type

– Double air valve design: the main valve is used for fast inflation (electric pump is full in 3 minutes), and the auxiliary valve supports fine-tuning of air pressure to avoid overpressure expansion caused by temperature difference in plateau areas (such as Colorado).

– Pressure relief valve: automatically senses air pressure exceeding 8 PSI and releases air to prevent the risk of bursting caused by extreme high temperatures (such as 50°C in Death Valley).

– Compatibility of air pumps

– Electric pump efficiency: select a 12V car interface or USB charging pump, flow rate ≥180L/min, and the inflation time of a 4-person tent is ≤5 minutes.

– Manual pump backup plan: equipped with a double-action foot pump (pressure is 20% higher than a single-action pump) to cope with power-free environments (such as remote camps in Yellowstone Park).

4. Construction logic: from “minute-level deployment” to “one-button storage”

The core advantage of inflatable tents is operational efficiency, but design defects will greatly increase time costs:

– Pre-connected air column system

– Using Color-Coded air path interface, the air column and air pump are quickly connected, avoiding the pole threading steps of traditional tents, and the construction time is shortened from 15 minutes to 3-5 minutes.

– Integrated ground mat design

– 0.5mm PVC ground cloth (wear resistance index ≥ 10,000 frictions) is integrated at the bottom of the tent, which saves extra laying time and blocks ground moisture (humidity is reduced by 70%, measured in Florida swamp campsite).

– Storage volume optimization

– The compressed size is ≤80×35cm (such as Big Agnes Titan 6), and the weight is controlled at 18-25 pounds, which is suitable for SUV trunk or pickup truck cargo space.

Scenario-based purchase decision tree

1. Family camping (such as Yosemite National Park)

– Choose a multi-chamber structure (2-3 compartments) + top ventilation window to balance privacy and air circulation.

– Recommended parameters: space ≥150 square feet, air column diameter ≥15cm.

2. Extreme weather (such as Texas storms)

– Choose a double-layer outer tent + wind rope anchor point, air column PSI ≥6, and ground nail pull-out force ≥50kg.

3. Lightweight backpack (such as the Appalachian Trail)

– Choose ultra-thin TPU air column (weight ≤ 5 pounds) + high reflectivity outer tent (such as MSR Habiscape), UPF sun protection index ≥ 50+.

Conclusion: Data-verified authenticity and reliability

Inflatable tents have evolved from “emergency equipment” to “all-round outdoor systems.” For example, users in Colorado have tested that the airtightness remains at -20℃ for 48 hours, and our tent can complete the deployment of a 6-person tent in just 4 minutes. Through structural innovation and rigorous testing, modern inflatable tents achieve a three-dimensional balance of wind resistance, waterproofness, and convenience, helping you cope with the diverse landforms and climate challenges in North America.

Reviews

There are no reviews yet.