Container tent purchase guide: structural design and adaptation strategy for Dubai’s harsh environment

As a professional container tent manufacturer, we are well aware of Dubai customers’ special needs for temporary buildings – from high temperature tolerance, dust protection to rapid deployment of large-scale events, structural design directly affects functionality and economy. This article is based on four dimensions: frame engineering, material science, modular system and scenario configuration, combined with Dubai localized test data, to provide an accurate purchase guide.

1. Frame structure: dual optimization of high temperature resistance and wind and sand resistance

Dubai’s climate is characterized by extreme high temperatures (up to 50°C in summer) and frequent sandstorms (wind speed ≥60km/h). The frame design must meet the following rigidity indicators:

– Main material selection

– Galvanized steel frame: thickness ≥2.5mm, hot-dip galvanized surface (zinc layer ≥120g/m²), salt spray corrosion resistance life of more than 15 years (in line with ASTM A123 standard), suitable for coastal areas (such as Jebel Ali Port).

– Node reinforcement: Laser-cut universal connectors are used, with a node tensile strength of ≥50kN, which is 35% more wind-resistant than traditional welded frames.

– Wind-resistant design

– Aerodynamic streamlined shape: top inclination ≥15° (such as temporary exhibition tents), reducing wind resistance area, and the measured structural displacement is ≤3cm when the wind speed is 80km/h.

– Ground anchor system: with spiral ground piles (length ≥60cm) or concrete counterweights (≥500kg/unit) to ensure stability under the soft desert foundation.

2. Enclosure materials: Synergistic solution for insulation and dust prevention

The enclosure materials of container tents need to balance insulation efficiency and light transmission requirements:

– Outer material

– PVC-coated polyester fiber: thickness ≥650g/m², UPF 50+ sun protection level, surface reflectivity ≥85% (in line with ISO 105-B02 standard), which can reduce the internal temperature by 8-12°C (actual measurement in Dubai summer).

– Anti-dust treatment: A double-layer Velcro + waterproof zipper sealing system is used to block the penetration of dust with a particle size of ≥50μm.

– Insulation interlayer

– Aluminum foil bubble film: Two layers of 5mm bubble layers (R value ≥1.5) are embedded, and the reflective heat radiation efficiency is increased by 40% compared with a single layer.

– Ventilation convection design: The top is equipped with an openable ventilation fan (air volume ≥300m³/h), and the side wall insect-proof gauze can achieve 6 full air exchanges per hour.

3. Modular system: rapid deployment and flexible expansion

Dubai’s commercial activities and construction projects have strict requirements on construction efficiency, and the following modular technologies need to be paid attention to:

– Unitized splicing

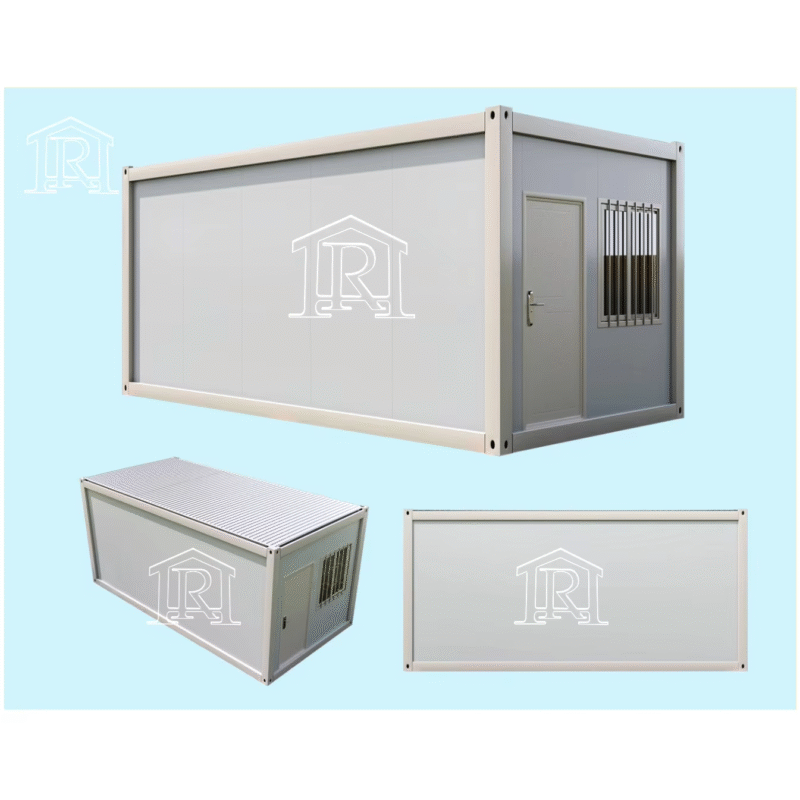

– Standard container size: 20-foot or 40-foot units (compatible with ISO transportation specifications), quickly expanded through plug-in connectors, and an area of ≥500m² can be built per day.

– Pre-installed circuit system: integrated cable tray and waterproof socket (IP65 grade), supporting plug-and-play lighting and air conditioning (such as 5kW split air conditioner adapted to a single box).

– Quick disassembly and assembly technology

– Tool-free assembly: Using Color-Coded numbered rods and buckles, a team of 6 people can complete the construction of a 100m² tent in 2 hours.

– Folding box: The thickness is compressed to 35cm under no-load state, and the logistics cost is reduced by 60%.

4. Scene adaptation: from temporary storage to high-end activities

According to the mainstream needs of Dubai, the following configuration solutions are recommended:

– Commercial exhibitions and summits

– Configuration focus: milky white tarpaulin with a light transmittance of 30% + LED embedded lighting (brightness ≥200lux), with glass curtain wall modules to enhance the business image.

– Case data: A 40-foot container tent can accommodate 80 conference seats, takes 4 hours to set up, and the ground load-bearing capacity is ≥500kg/m².

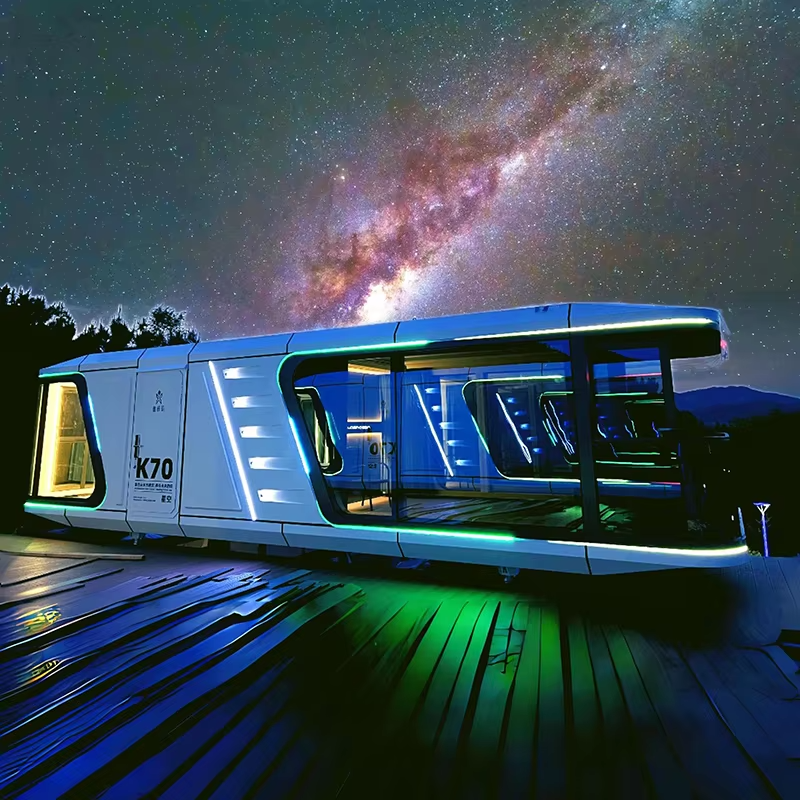

– Desert tourist camps (such as Bab Al Shams Resort)

– Configuration highlights: double-layer insulated roof + external sunshade deck (extended 2.5m), integrated gray water recovery system (water storage capacity ≥1000L).

– Actual test results: When the external temperature is 48°C at noon, the energy consumption is reduced by 22% under the condition of air conditioning set at 26°C.

– Industrial temporary storage (such as DMCC Free Zone)

– Configuration highlights: fireproof tarpaulin (B1 flame retardant) + explosion-proof electrical system, suitable for -20°C to +70°C temperature zone (such as refrigerated container modification solution).

Conclusion: Data-driven scenario-based decision-making

Dubai customers need to make comprehensive choices based on the use cycle, environmental load and functional scalability. For example, lightweight folding containers can be used for short-term exhibitions (≤7 days), while long-term camps (≥1 year) should be equipped with galvanized steel frames + UV protection coatings. Through structural innovation and local adaptation, modern container tents have achieved the ultimate efficiency of “72 hours from transportation to operation”, becoming the core temporary building solution for desert economies.

Reviews

There are no reviews yet.